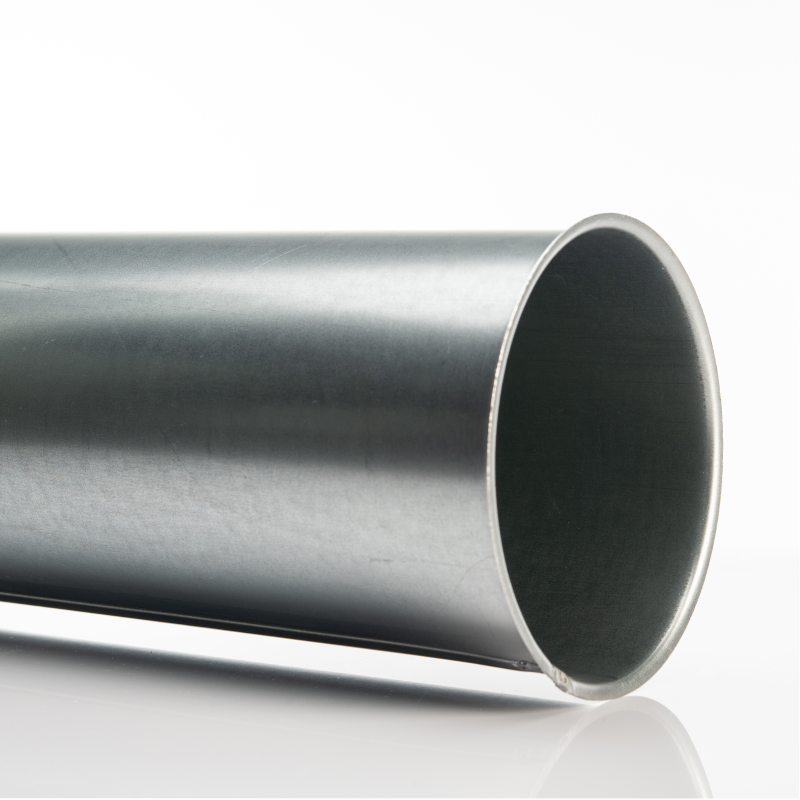

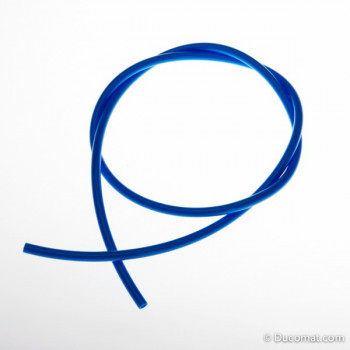

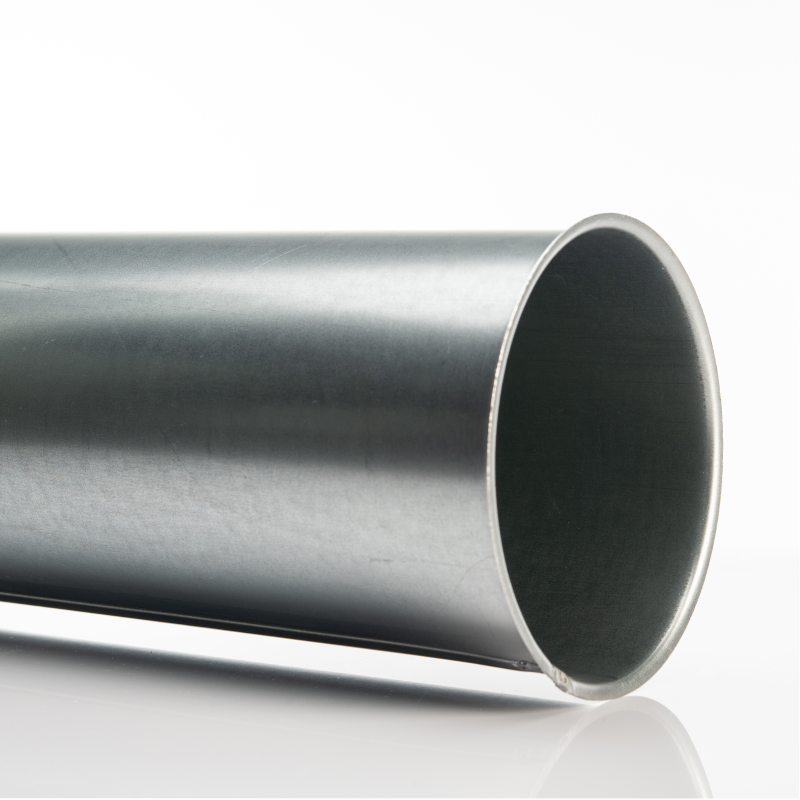

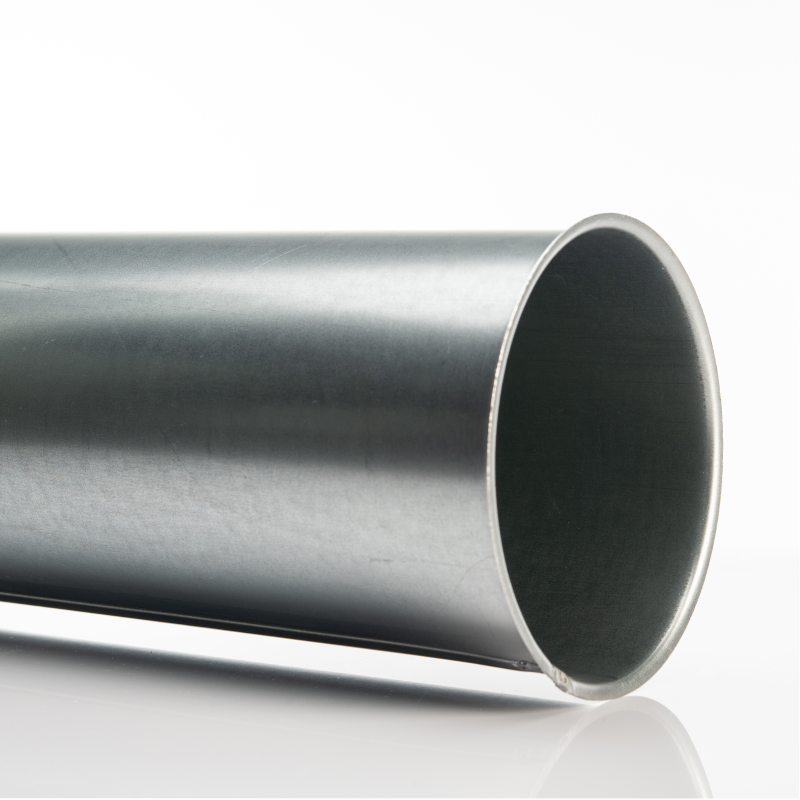

Galvanized steel pipe, Ø 80 mm, thickness 0.7 mm, laser-welded lengthways, 1.5 m long, with edges to suit various types of ring. These airtight pipes are ideally suited for creating a network for woodshop dust collection.

The pipe which is 1.5 m long and with Ø 80 mm, has a 5 mm edge at each end. In combination with our rings, they enable the pipes and our other components to be assembled into a network of woodworking dust collection ducts.

The various types of rings enable the pipes to be interconnected. You can choose between models that are assembled with screws, with or without seals, with lever locks, ...

Of course, it is possible to custom fit your pipes using an angle grinder, and to create a 5 mm turned-down edge using a pair of pliers and a hammer. Once you have measured the length necessary, make sure to add the length required to create your flanges.?Telescopic pipes of 80 mm diameter will facilitate making the necessary joins.

The quality of an industrial dust collection system clearly depends on its designer's technical and aeraulics know-how, as well as the choice and quality of the components used to build it.

The pipes used to build the woodshop vacuum system must meet various quality criteria:

Galvanized steel pipe, Ø 80 mm, thickness 0.7 mm, laser-welded lengthways, 1.5 m long, with edges to suit various types of ring. These airtight pipes are ideally suited for creating a network for woodshop dust collection.

icon

icon