Rectangular suction manifold made of galvanised steel sheets that are 8 mm thick. The outlet diameter is 200 mm, while the inlets will have a maximum diameter of 160 mm. You can connect this suction manifold for carpentry/joinery shops to your dust extraction system using our range of clamps.

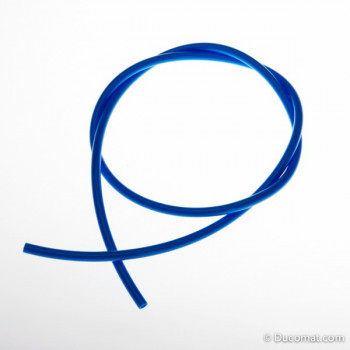

The suction manifolds, also called suction hoods, are used to distribute the main air flow from the ducting of a woodworking machine to the different extraction points installed by the manufacturer of this machine. There may be multiple extraction points of varying diameters, as is often the case for edge gluers or tenoning machines. The position of the tools of the woodworking machine tools, and thus of the extraction points, do not permit connections with rigid suction pipes, so that flexible suction hoses must be used.

This suction manifold, or suction hood, has a 5 mm rim at the upper end and smooth edges at the lower suction ports. The 5 mm edge enables you to connect the ducting network of your industrial dust collection system using our clamps. The lower suction outlets, whose diameter you will have specified beforehand, have smooth edges, to which you can attach a flexible hose of the corresponding diameter. We recommend using PU hose clamps.

Click on the following link for an image of the installation of a suction manifold for a carpentry/joinery shop : https://www.ducomat.com/fr/p31-configurateur-systeme-aspiration

The quality of an industrial dust extraction system depends primarily on the technical and aeraulics expertise of its designer, but also on the selection and quality of the components used to implement it.

The suction manifold selected for use in a dust extraction system for carpentry/joinery shops must meet various quality criteria:

Rectangular suction manifold made of galvanised steel sheets that are 8 mm thick. The outlet diameter is 200 mm, while the inlets will have a maximum diameter of 160 mm. You can connect this suction manifold for carpentry/joinery shops to your dust extraction system using our range of clamps.

icon

icon