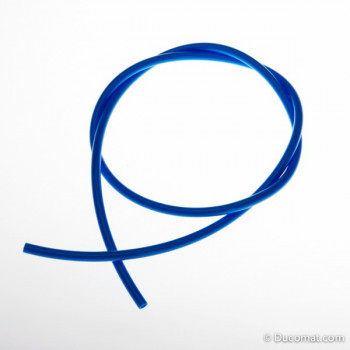

Branch pipe with branch at 45°, Ø 100 mm - Ø 80 mm - Ø 100 mm made of 0.8 mm thick galvanized steel. The Ø 80 mm branch is at 45° in position D2. Its edges allow the fitting of various types of clamp. This branch pipe is completely airtight, and ideally suited to creating networks of suction ducts for the woodworking industry.

This single branch pipe has a branch at 45° from its axis. Its outlet Ø is 100 mm, the inlet Ø is 100 mm and the branch Ø is 80 mm. There is a 5 mm edge at the ends of the branch pipe, to enable easy assembly with other components of the extraction system for the woodworking industry. The branch of the pipe is often extended with a bend to angle the ducting towards the woodworking machine to be connected. In principle, branch pipes are installed with the branch in a horizontal position. If the hood of the machine to be connected is located below the branch inlet, a 90° bend should be installed. Then the duct should go down from the bend towards the extraction outlet of the machine.

Using our various types of ring, the branch pipes can be assembled easily, pushing the 5 mm edges of the components against each other. Our rings all have the same function, but they each have specific characteristics. Some are fitted with a sealing ring, others close by means of a lever.

The quality of the build of an extraction system for the woodworking industry depends mainly on the technical and aeraulics expertise of its designer, as well as the choice and quality of the components used to build it.

The pipes used to build the extraction system for the woodworking industry must meet various quality criteria:

Branch pipe with branch at 45°, Ø 100 mm - Ø 80 mm - Ø 100 mm made of 0.8 mm thick galvanized steel. The Ø 80 mm branch is at 45° in position D2. Its edges allow the fitting of various types of clamp. This branch pipe is completely airtight, and ideally suited to creating networks of suction ducts for the woodworking industry.

icon

icon